Did The Horn Honk? The Modern Revolution in Horn Design

What is “Honk” Sound

The term “honk” in audio is often associated with an undesirable coloration that gives a nasal or hollow character to the sound. This phenomenon can arise from several combined sources:

-

Throat resonances: Unintended resonances within the throat of a horn can introduce peaks in the frequency response, leading to a honky character.

-

Time-domain anomalies: A combination of throat resonance and an abrupt termination of the horn profile can create reflections and energy storage effects, resulting in temporal smearing.

-

Path length differences: A significant delay caused by a long acoustic path in the horn compared to other frequency components can lead to phase cancellation, creating irregularities at the crossover point.

-

Propagation modes in the horn: Certain horn geometries, especially older and curved designs with non-optimized profiles, can support unwanted propagation modes (cutoff modes). These modes interfere with the main signal, introducing frequency and phase anomalies that contribute to a honky sound.

-

Diaphragm breakup: Older compression driver diaphragms exhibited breakup modes at lower frequencies than modern designs, potentially contributing to a honky coloration.

History

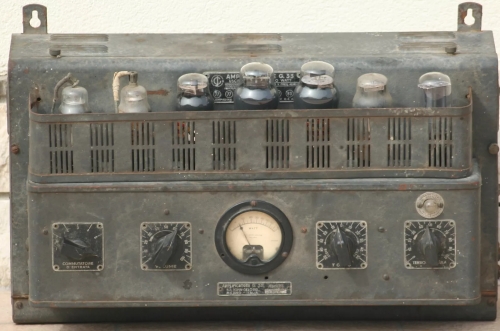

At the beginning of the audio industry, amplifiers were unable to deliver significant power. Early tube amplifiers could only produce a few watts:

To compensate for this limitation, the audio industry relied on high-efficiency acoustic loading — at the expense of everything else. This focus on maximizing efficiency with a very long throat came with severe trade-offs in linearity, directivity control, resonances, viscothermal losses, higher-order modes (HOM), and increased distortion at high frequencies — together, these phenomena can be perceived as “Honk”.

This approach also led to significant compromises in overall sound quality and directivity control.

A prime example is the Western Electric 15A, introduced in the 1920s:

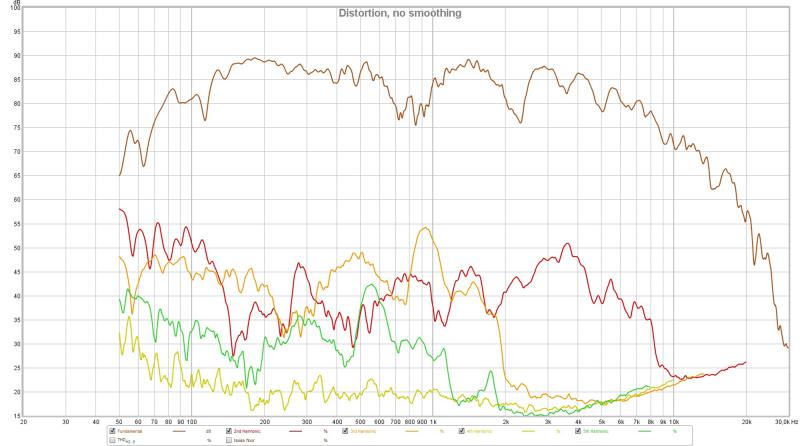

With measurement and distortion at 90dB SPL at 1m with a Lamar compression driver:

Over time, this early limitation wrongly became a defining trait of all horn-loaded systems, giving rise to a persistent and unfounded cliché. Despite decades of advancements in horn design, many still associate horns with this outdated flaw, even though modern designs have completely eliminated the causes of “honk.”

How Audio Solved It

The issues that caused the “honk” sound a century ago have been progressively eliminated thanks to technological advancements. Key improvements include:

-

Amplifier advancements: With the transition from low-power tube amplifiers to Class AB and now Class D, power is no longer a limiting factor. We can now use the adapted horn loading, optimizing horn throat design while respecting wavefront propagation.

-

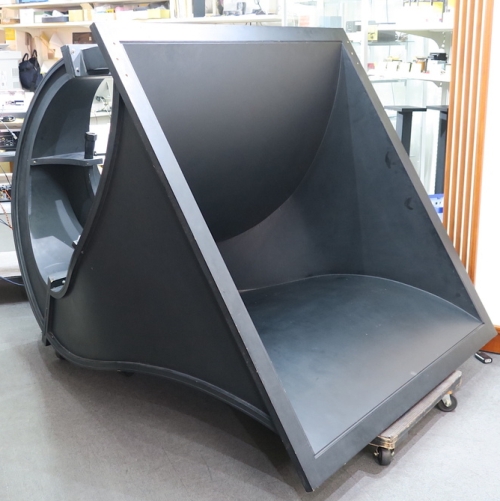

Finite Element Analysis (FEA) and simulation: Modern modeling tools allow engineers to simulate wavefront behavior with precision, ensuring optimal throat shaping and loading without introducing unwanted artifacts.

-

DSP and active filtering: Digital processing has definitively solved the delay issues between components, making phase alignment and crossover transitions seamless.

-

Fluid horn profiles: These advanced geometries eliminate throat resonances, further enhancing clarity and accuracy in sound reproduction.

-

Improved compression drivers: Innovations in diaphragm materials, surround design, and phase plugs have pushed time-domain issues far beyond the range of human hearing, effectively eliminating artifacts associated with older designs.

-

Better understanding of wavefront behavior and directivity: Over the years, extensive research has deepened our knowledge of how wavefronts propagate within horns, helped by FEA. We now fully understand the importance of directivity matching between drivers to ensure a smooth frequency response tansition at crossover and avoid accidents at the crossover region.

The Role of Crossover Optimization and Directivity Matching

A common misconception is that midrange crossovers inherently degrade sound quality.

However, modern design techniques ensure that, when properly implemented, crossovers pose no issue. By precisely controlling:

- Delay

- Phase alignment

- linear SPL

- Crossover frequency chosen considering distortion and directivity matching

- Proper and stronger slope

Properly implemented systems achieve seamless transitions between drivers without introducing audible artifacts.

One crucial aspect often forgotten is directivity matching at the crossover point. If the directivity patterns of adjacent drivers do not align properly, this can lead to a perceived “empty midrange,” where energy is either lost off-axis or becomes accidented.

By carefully designing the crossover region to maintain a consistent radiation pattern, we ensure a smooth and natural transition across the frequency spectrum.

Today’s tools, such as VituixCAD and REW, allow for advanced crossover simulation, measurements and optimization of crossover design including directivity match, ensuring perfect integration between components. Thanks to these technologies, crossover points in the midrange are no longer a limitation but rather an integral part of achieving optimal performance.

Conclusion

The so-called “honk” sound was a byproduct of early horn-loaded systems, where efficiency was prioritized over all other design considerations due to amplifier power limitations. These compromises led to resonance issues, poor directivity control, and time-domain distortions that reinforced the negative perception of horns.

However, modern advancements in amplification, simulation, DSP, horn geometry, and compression driver technology have completely eliminated the root causes of “honk”. Today, properly designed horn-loaded systems benefit from optimized throat loading, controlled directivity, and seamless crossover transitions. Software like VituixCAD ensures precise phase alignment, time correction, and directivity matching in crossovers, making them transparent and free of artifacts.

In short, “honk” is a relic of the past, a problem solved long ago. Properly implemented horn designs now offer high efficiency, controlled dispersion, and accurate sound reproduction without compromise.

The outdated cliché of honky horns persists, but the reality is that modern constant directivity horn systems, when properly designed with loading capacity as we do, achieve unmatched linearity, phase coherence and neutrality, setting the benchmark for high-performance loudspeaker design.