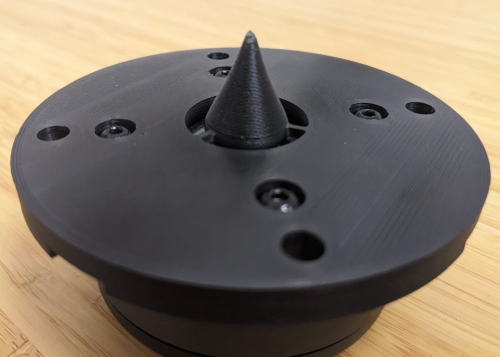

Compression Driver

What is a compression driver and comparison with dome Tweeter

A compression driver acts as a high-volume plane wave generator, unlike a regular tweeter, so their design and usage differ.

While it is possible to control and select the radiation angle of a compression driver, achieving this with a regular tweeter is more challenging.

We usually talk about waveguides for tweeters and horns for compression drivers.

With a tweeter, we mainly “guide” the sound, as this device doesn’t provide significant acoustic loading. Due to their limited SPL capabilities, tweeters are primarily dedicated to close-range or monitoring applications, while compression drivers are better suited for medium to long-distance use.

For mid-distance listening, a horn paired with a compression driver is more appropriate.

Throat Size

The throat size generally dictates the high-frequency control of the horn, and thus its constant directivity behavior.

The larger the throat size, the less high-frequency control we have. However, there are design tricks to mitigate this, as seen in our bi-radial horn or X-Shape / M-Shape horns.

1" compression driver:

They are relatively inexpensive but cannot go very low in frequency. The best among them have a low-frequency limit around 950–1000 Hz (BMS and 18Sound).

The throat is tiny, so the radiation control occurs at high frequency.

2" compression driver:

This is a historic size with limited high-frequency control.

Today, some 2" drivers are still used for very specific applications:

providing high SPL and low-end response without regard for top-end directivity control.

These tend to be used in line arrays for long-throw applications, such as the Celestion Axi2050, designed specifically for that purpose.

Using 2" compression drivers is not recommended for our typical usage.

1.5" or 1.4" compression driver:

This size is ideal, offering lower frequency extension with a moderate throat size.

Most “2 inch” drivers are actually 1.5" drivers with built-in adapters, like the JBL 2450 or TAD TD4002.

From the horn’s perspective, it is more efficient to use a true 1.5" driver rather than a 2" version.

1.4" drivers have a 3" or 3.4" diaphragm, which pushes breakup frequency higher.

1.5" drivers have a 4" diaphragm, allowing better max SPL and lower distortion at low frequencies.

On our 1.4/1.5" Bi-radial horn, we use a smooth pinch to push the control as if it were a 1" throat, combining the best of both worlds.

We apply a similar principle in the X-Shape and M-Shape horns.

Exit Angle & Flare

A compression driver has an exit angle, sometimes referred to as rapid flare vs slow flare. This is the exit angle of the device in degrees, usually given as a semi-angle. For example, a TD 4002/4003 has a semi-angle of about 4–4.5°, so the full coverage angle is roughly 8–9°.

The larger the flare, the more difficult it is to smoothly transition to the horn’s coverage angle (e.g., a semi-angle of 45°, or full coverage 90°).

Some compression drivers have a large semi-angle, called rapid flare, which is not ideal for our applications.

We prefer slow flare angles, as close to 0° as possible. The JBL 2450SL has a 0° flare (no flare), which is why I generally recommend it for 1.5" drivers; it is also available used at reasonable prices.

The 1.4" 18Sound ND3 family and FaitalPRO HF1440/1460 also have slow flare angles, which suits our needs well.

Note: Regarding diaphragm materials, Truextent’s Be is embossed beryllium, not vapor-deposited Be like TAD uses (which is more expensive). So even if it’s Be, it is quite different from TAD’s process.

Setting a new diaphragm precisely in a compression driver is difficult, although modern drivers make this easier. Diaphragm characteristics are integrated into the overall device design, so swapping diaphragms doesn’t always yield improvements—and sometimes can worsen performance. Be cautious when changing diaphragms.