How to do great cabinet, braces and stuffing

Dimensions

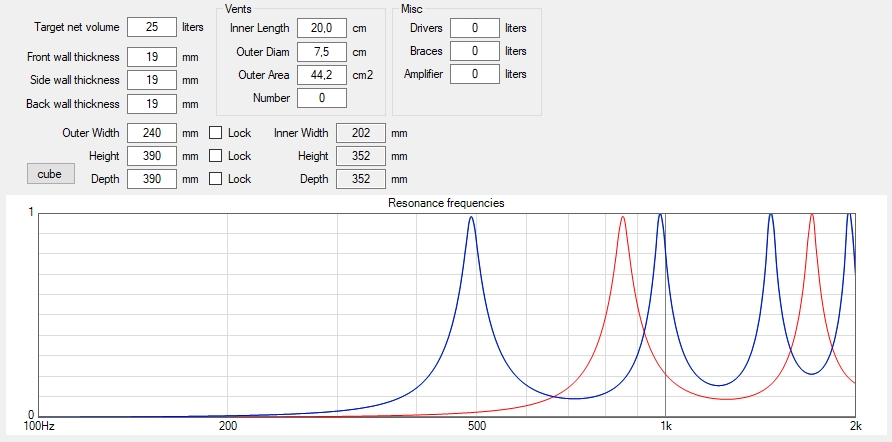

We begin by defining the box volume and the primary vent dimensions using VituixCAD.

We aim to avoid internal dimensions that are multiples of one another, as this will lead to cumulative and reinforcing standing-wave resonances at the same frequency.

VituixCAD offers a useful tool for this: Tools → Auxiliary → Box Volume

We can see that the box has no resonances below 300 Hz, because the wavelengths are too long compared to the internal cabinet dimensions.

This is almost always the case for subwoofers, where resonance wavelengths are much larger than the enclosure dimensions, reducing the need for stuffing in sealed design to increase the subwoofer’s perceived internal volume.

Braces

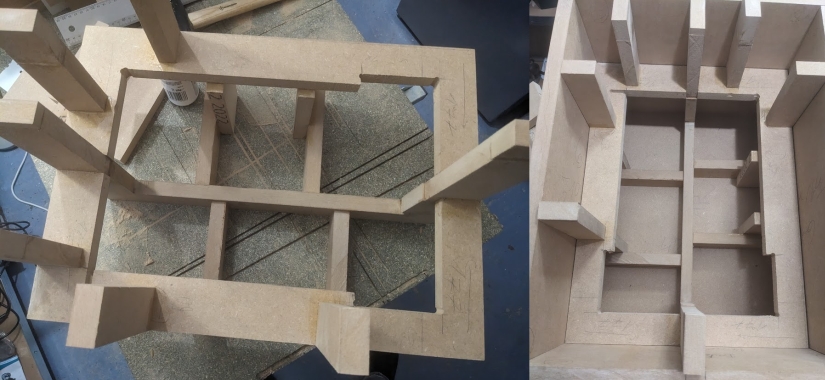

The I-beam (IPN-style) brace offers the best ratio of stiffness to occupied volume and provides rigidity across the full frequency range.

This is not the case with a simple cross brace centered in the box, which only reinforces at a narrow frequency.

Corners and panel junctions (typically at 90° in rectangular enclosures) are already structurally strong.

It’s in the center of each large panel that additional stiffness is required.

A cross brace without substantial reinforcement is ineffective.

Only strapping structures like the IPN-style brace provide broadband structural support.

Stuffing Materials

Polyfill

Low-density materials such as Poly-Fill or pillow stuffing are commonly used in sealed enclosures to simulate a larger internal volume, but they are not particularly effective at absorbing internal reflections.

Waste fiber insulation

For side-wall damping, the best material is 20 mm (1 inch) waste fiber insulation used in automotive applications:

Waste-fiber insulation is a high-density damping material.

It is applied to all internal surfaces except the front panel and brace, with the thickness doubled on the top and bottom panels for tall speakers to address longer-wavelength resonances.

This treatment naturally adds a bit of virtual volume, helping to compensate for the space occupied by the internal bracing — exactly what we want.

Woofer Stuffing

Because sealed woofers operate over a wider and higher passband than subwoofers, they are more likely to excite box resonances.

If you use two woofers in the same cabinet, it can be beneficial to separate their volumes internally to reduce the wavelength of resonances caused by an overly large internal dimension.

In some cases, creating an internal partition between the horn section and the woofer section can also shorten the largest cabinet dimension, helping to reduce long-wavelength resonances that are more difficult to damp. However, this approach reduces the available volume for the woofer because part of the enclosure is isolated for the HF section.

Vented Woofer Enclosures

Since the alignment is already tuned close to a Bessel response, placing stuffing in the path between the woofer and the port introduces resistive losses. These losses reduce port efficiency, shift the tuning, and, more importantly, decrease bass extension by lowering port SPL.

In vented enclosures:

- No Poly-Fill is used.

- Absorbing material must not be placed in the direct path between the woofer and the port.

- Waste-fiber insulation is applied to the internal walls, except the front panel.

- In the cabinet’s largest internal dimension, where the wavelength of the main reflection is long, the insulation layer should be made twice as thick to improve damping effectiveness.

Sealed Woofer Enclosures

In this case, both the apparent volume increase and the damping of internal reflections become relevant.

In sealed enclosures:

- A combination of Poly-Fill and waste-fiber insulation may be used.

- When dealing with the cabinet’s largest dimension, the waste-fiber layer should also be doubled in thickness to better attenuate long-wavelength reflections.

- This approach increases the effective volume and reduces internal resonances, as shown in the picture.

Subwoofers Stuffing

For subwoofers, the practice is simple: in sealed designs, Poly-Fill is used extensively to increase the subwoofer’s perceived internal volume, while in vented designs it is generally avoided — or applied only in small amounts — because internal resonances are usually outside the woofer’s passband and we don’t want to reduce port efficiency without any other benefit.

Resonances inside subwoofer boxes are usually not an issue, as the wavelengths involved are much longer than the enclosure dimensions.

This means standing waves are effectively absent, and wall lining with waste-fiber insulation brings little to no benefit.

Summary

-

Poly-Fill: Increases the woofer’s perceived internal volume but has almost no effect on resonances due to its low density. Easy to use in sealed enclosures to adjust perceived volume.

-

Waste-fiber insulation on walls: Reduces and even suppress resonances thanks to its high density, while also slightly increasing perceived volume.

-

Port consequences: The more damping is applied, the more port efficiency is reduced. It’s a balance between resonance damping and port efficiency. Avoid placing damping in the path between the port and the driver to preserve port output, especially when using high-density stuffing.

This aspect usually doesn’t concern vented subwoofers, as there is almost no need for stuffing inside, as noted in Subwoofers Stuffing section.

-

Usual usage:

- Vented Woofer: Waste-fiber insulation on walls

- Sealed Woofer: Waste-fiber insulation on walls and, if adding volume is needed, Poly-Fill

- Vented Subwoofer: Usually nothing

- Sealed Subwoofer: Poly-Fill in large amounts to add volume