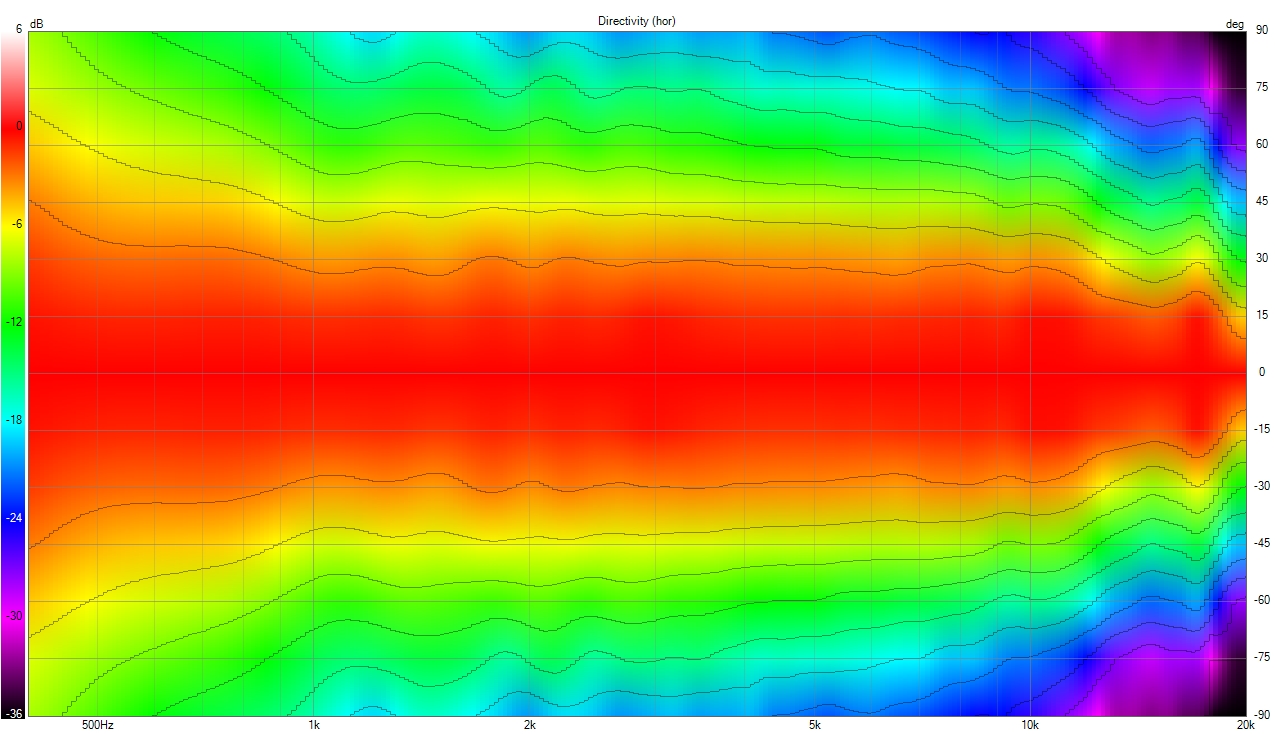

Polar map, Apex and distorted polar plot

Polar map, polar plot, contour plot

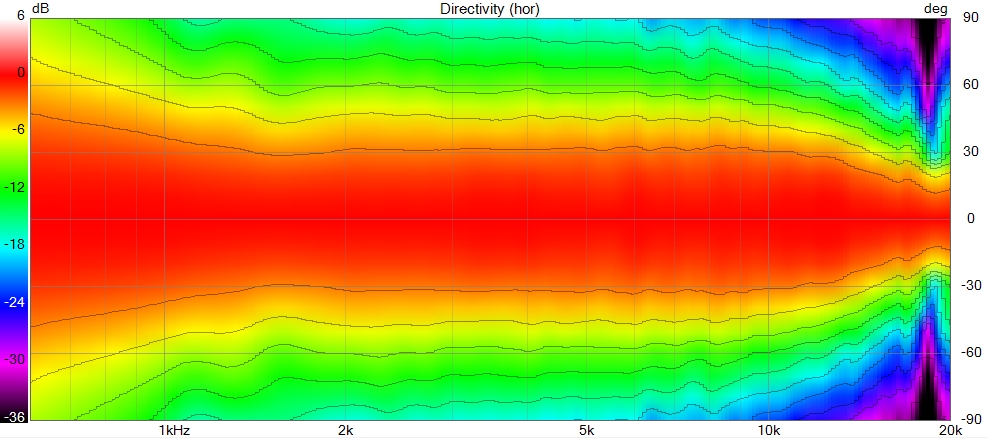

Heavily used at AudioHorn, the polar map or in fact the contour plot in our case, is a graphic representation of the energy radiation provided by a device, in dB scale versus angle in degrees.

It obtained by measuring the speaker, far away from reflective surfaces including floor, every 5 or 10° on an vertical axis by turning the speaker on itself, not moving the mic, at a precise distance and with gated measurements.

The contour plot has the advantage to make all the frequencies visibles in one graph:

Where the -6 dB, here the transition from red to yellow by convention, defines the opening angle of the horn or waveguide. As it’s flat we can also said that the directivity is constant, we use VituixCAD for visualization here.

But turning the speaker on itself means precisely using an axis, and to define where it is?

It’s why we will talk about Apex or apparent Apex.

What is Apex ?

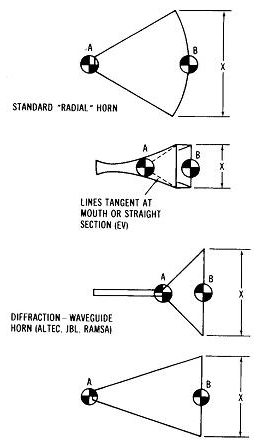

The apex is a point where the horn or waveguide’s profile axes virtually meet, if the profile is curved, which is systematically the case today and in our profile, it’s where the opening axes used to calculate the profile meet.

This is not the source of emission although by choice some designers have made the two coincide. It’s often not the same between horizontal and vertical, here point A is the Apex when B is considered as the baffle:

This point allows to properly characterize a “guided” transducer (waveguide and horns but also coaxial driver) to have real directivity measurement.

To measure a direct-radiating loudspeaker or one with a very short/small WG, it doesn’t matter and rotating around the baffle plane is sufficient.

In the case of polar measurement of a single element, we will place the mic at the height of the targeted element and rotate around the apparent apex.

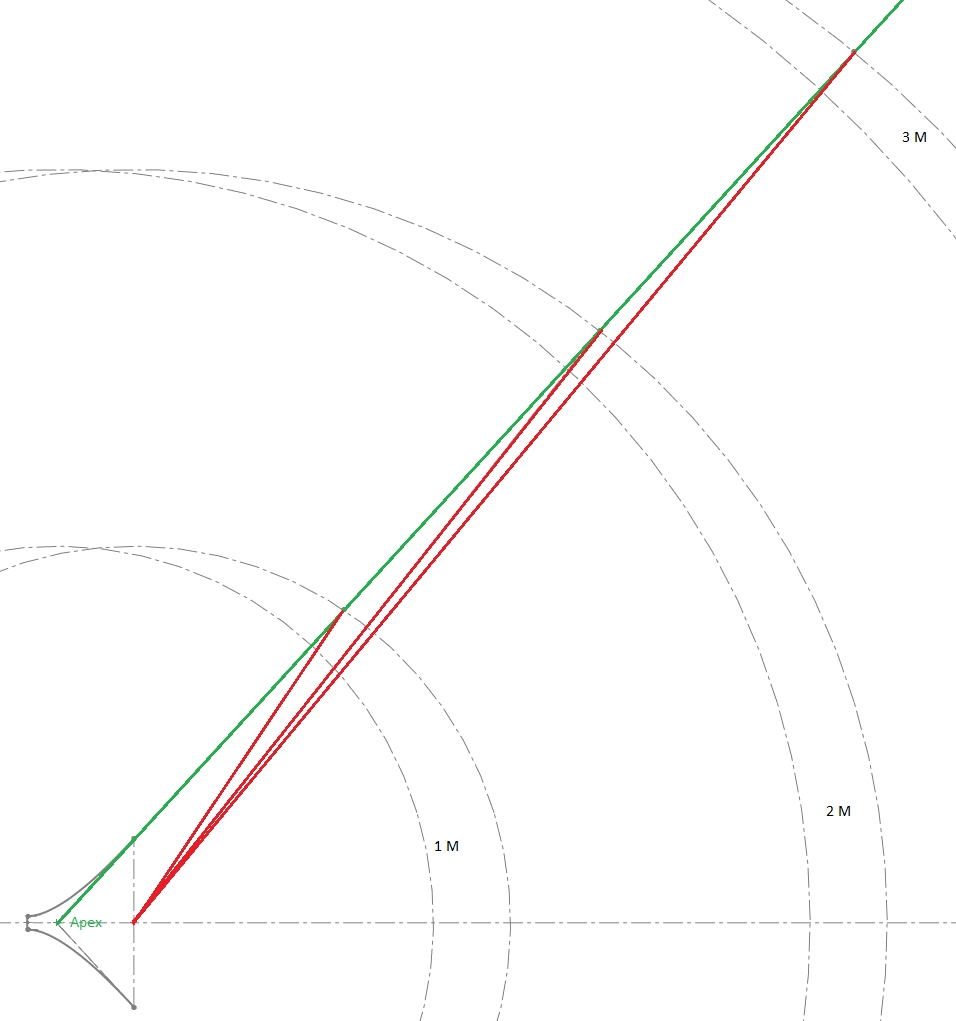

Rotating around something other than the apex for a horn or waveguide will introduce a “distorted polar plot”: The closer we measure, the larger the mouth and deeper the apparent apex is, the more crucial this point is.

Distorted polar plot

The distorted polar plot is not a distortion in the usual sense in audio, it should be seen as a trigonometric error between the position of the microphone, the apex and the width of the horn mouth, The shape of the directivity will generally be correct but the opening given by the angle at -6dB, will be in the wrong position, sometimes to a large extent, we are talking about a difference of the order of 10°. The entire energy distribution is distorted.

Here the green line is aligned with the opening of the horn and also shows how to find the Apex and the red lines are the equivalent by rotating around the baffle, but this is valid at any point.

Note: A horn is never measured free-air without full roundover or ISO baffle, if not a lot of midrange narrowing will appear.

We can see on this diagram that the further from the DUT (Device Under Test) we are, the smaller the difference is between rotating arround the baffle compared to rotating arround the APEX.

So in a close measurement of a large horn, the rotating axis must be close to the horn’s Apex.

Hence the fact that a complete speaker is measured in anechoic chamber around 3m, as the apex being not the same between the different elements of the speaker.

We can then ask ourselves what to do when measuring a complete speaker fairly closely when we don’t have these perfect conditions, two cases are available to us:

-

The guided part is small and does not go low so much, a point equidistant between the mid-woofer Apex and the “loaded” part, will suffice.

-

The guided part goes down (let’s say 700Hz), it covers a big part of the reverberant field, that is after the Schroeder distance, below it’s the modal field.

This is where directivity control is the most important because it will have a very audible impact in the reverberant field more than in the modal field.

In this case, we will directly choose the Apex of the top guided part.

In other words, the closer you are, the more interest there is in using the apparent apex to be in the “truth”.

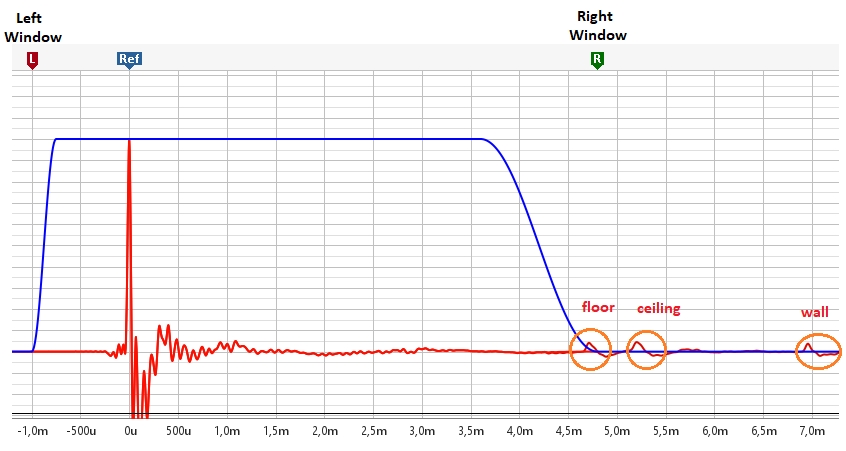

Gated measurements

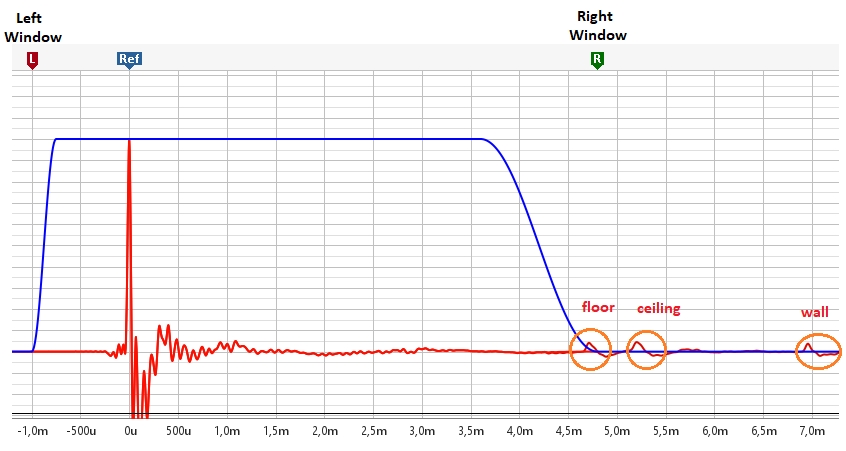

Even if you measure at 1m of the Apex you will have a floor/ceiling bounce that will impact your measurement in the lower range, you can visualize it with a tool in VituixCAD to see when (in time), according to distance and height position of elements, you will have it.

The way to do is: In your measurement tool, usually REW, you have to look at the Impulse, check where the accidents due to surfaces occur in time and then gate the measurement just before the first accident as shown here:

Here we put:

- Lef Winfow: 1ms

- Right Window: 4.8ms, just before floor reflection

Be also sure that Ref is on the impulse of the driver because at 75 or 90° the wall reflection can be more important in volume than the driver itself due to the fact that we turn the speaker or horn. So the measurement tool can in some cases choose the wrong Ref and put it on a reflection, so we have to move the ref to the real driver impulse, to the left.

A gated measurement avoids accounting for reflections and slightly smooths the low frequencies depending on the chosen window value, with a proportional effect as frequency decreases. For low or midrange horns, the horn must be moved further away from reflective surfaces to extend the time before reflections enter the window.

Important: When measuring and then gating a high-frequency horn, the speaker is naturally positioned at a certain height above the ground. It can be useful to place it higher so that the floor reflection arrives later in time. Positioning the device halfway between the floor and the ceiling is usually optimal.

For a woofer, avoid placing it too close to the floor. Use something to raise it as much as possible, ideally also around the midpoint between floor and ceiling. This allows for a longer gate window and therefore better frequency resolution.

A point about Scale

We need to pay attention to scale of the polar plot. A “half-space” option in VituixCAD displays the polar response over 180° instead of 360°. If we stay in the 360° mode, the scale is affected, and the polar response may appear more consistent than it actually is.

The same issue exists with the color scale, where using solid colors for a 2 or 3 dB range instead of a gradient can hide certain problems.

Lastly, an even simpler issue is with polar maps that start at 0 dB, a proper polar map should account for everything above 0 dB, rather than ignoring it.

Using the same color for ranges like +6 dB to -2 or -3 dB (and sometimes even down to -6 dB) also completely obscures the true response of the horn.

The yellow color should also be on the -6dB and not -10dB to not hide everything in the red color.

Ground plane method

Since it is not representative of real-world usage, it should not be interpreted as an absolute reference but rather as a comparative method.

It is particularly useful for consistently comparing different components designed for the same low-frequency range.

Placing the microphone on the ground eliminates ground reflections but introduces the ground effect, where the reflection from the floor creates a virtual image source below the ground plane.

At low frequencies, where the wavelength is large compared to the distance between the real and virtual sources, the two sources combine constructively, resulting in a 6 dB increase in SPL on-axis. This ground effect can be removed from the SPL measurement using a mathematical correction function, making the method reliable for low-frequency SPL and distortion measurements.

However, at higher frequencies, the shorter wavelengths lead to destructive and constructive interference patterns between the real source and its acoustic image, causing phase cancellations and artificial lobing. This makes the method unsuitable for polar measurements, as it does not accurately represent the speaker’s natural radiation pattern.

Don’t underestimate wind, natural noise, or passing vehicles in this methodology, as they can significantly impact the results.

While this method is well-suited for SPL and distortion measurements in the low-frequency range, it is not appropriate for directivity measurements (polar plot). The ground reflection creates a virtual image that interferes with the direct sound, altering the measured radiation pattern and making the results unreliable for mid and high-frequency horns.

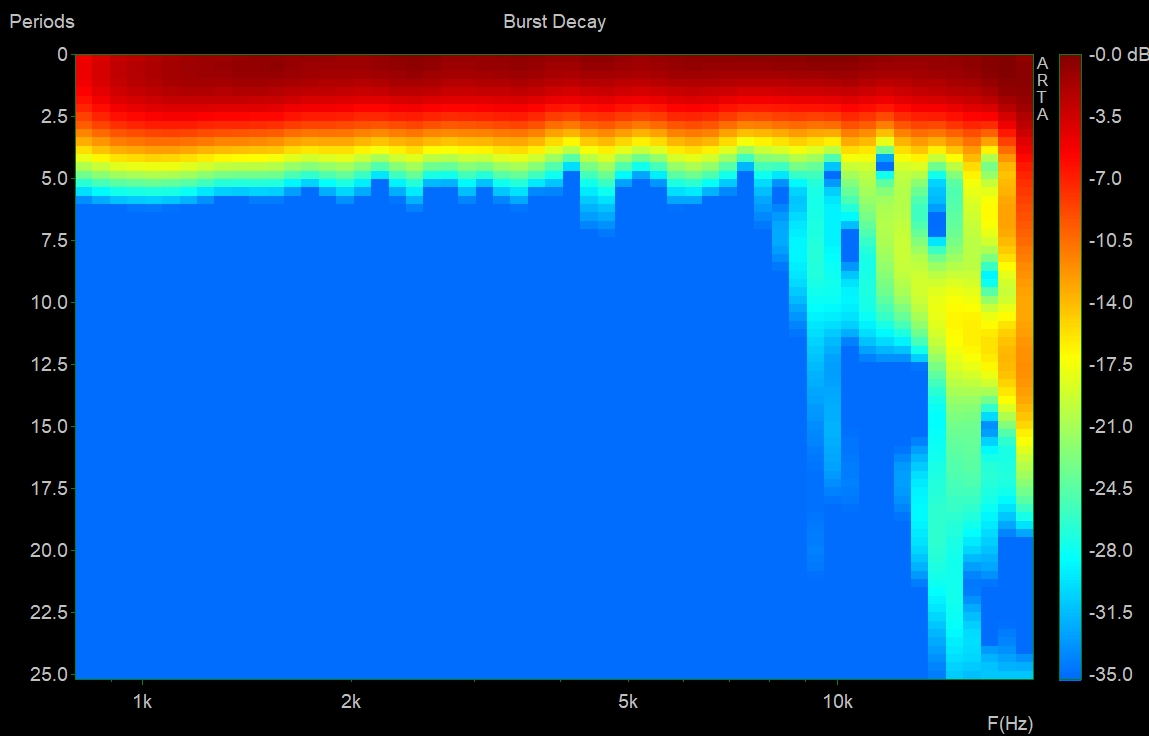

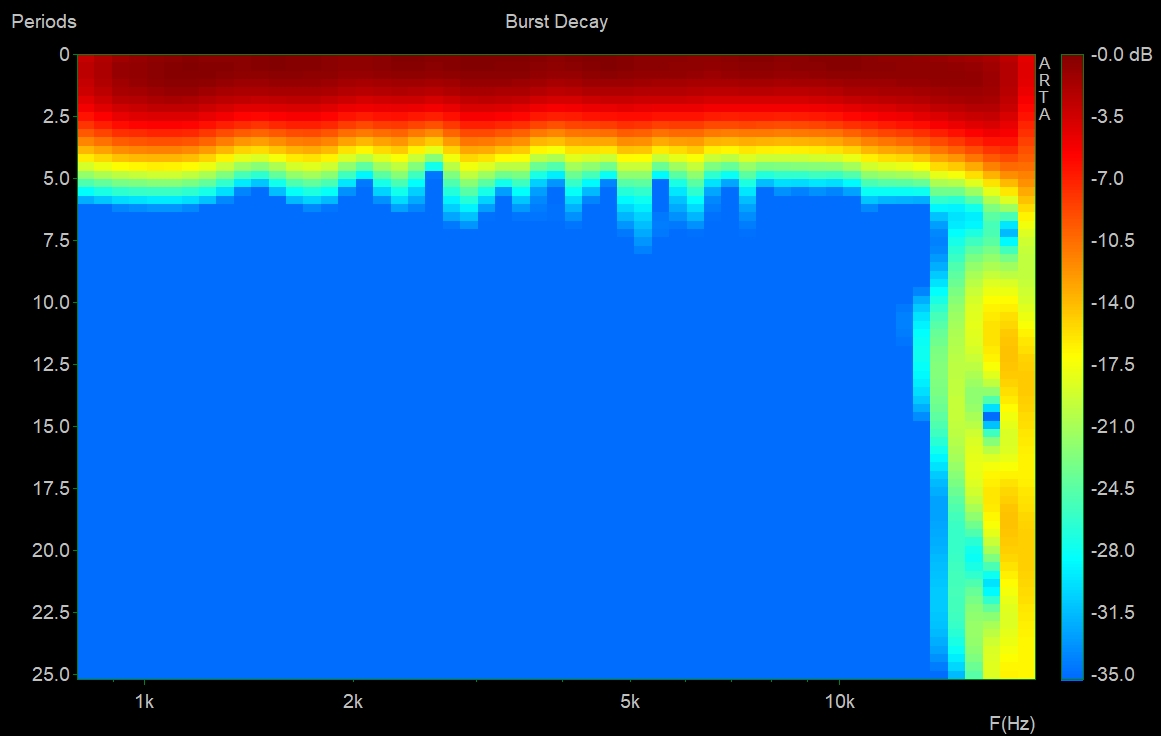

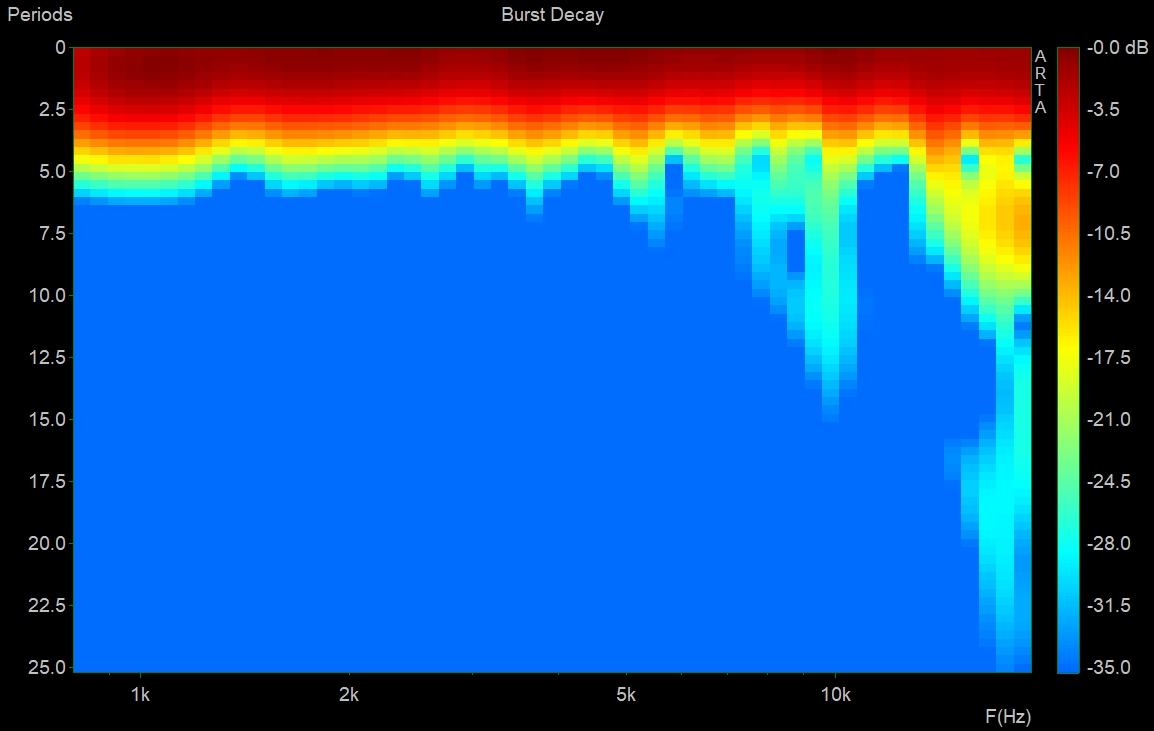

Time domain and breakup impact of polar

Even when normalized, time-domain issues have a significant impact on polar measurements. This is because when a time-domain problem occurs within the driver—due to diaphragm breakup, phase plug anomalies, or other factors—the resulting wavefront deviates from ideal plane wave radiation and no longer perfectly follows the horn profile. This leads to irregularities in the polar response.

If the breakup is well-damped or the time-domain disturbance is minor, the effect remains subtle. However, in the case of severe breakup caused by a rigid diaphragm, the impact becomes much more noticeable. Rigid diaphragms are not inherently bad; they push time-domain issues to higher frequencies compared to softer diaphragms. However, the breakup they introduce is often more abrupt, leading to distinct anomalies in the polar response.

Another point to take into consideration: the more energy (SPL) we send into the breakup region, the more visible the artifacts will be. Therefore, the higher a horn maintains constant directivity at high frequencies, the more the breakup effects will appear on the polar response.

For example:

- With a rigid diaphragm driver such as the Faital HF108R:

- With a very well-controlled hard diaphragm unit, the 18Sound 1095N:

- A plastic annular diaphragm, which is less sensitive to breakup due to its shape, the BMS 5530:

We can see that even when normalized, time-domain behavior has a direct impact on polar measurements due to deviations from perfect plane wave radiation.

Time domain accidents due to the driver have a direct impact on normalized directivity.

Measurement Context

In polar measurements, it is crucial to characterize what we actually want to analyze—the horn—rather than external factors such as the environment or even diaphragm tuning.

Horn integration

A horn without a roundover should not be measured in free air. When a horn has a fluid profile, such as ours, the best approach is to use the final roundover return that will be used in the speaker, as advised on the website:

These are very important in measurement and also in the final speaker:

More information about Midrange narrowing and beaming in our dedicated article.

Diaphragm tuning impact

Diaphragm tuning is an important factor in the measurement context, as it can vary even within the same reference. In modern drivers, there are typically two measurements: one for the diaphragm and another for the compression driver.

By subtracting these values and adding adjustment rings of 0.05, 0.1, or 0.2 mm, we can set the proper diaphragm height:

Below are two measurements of the same compression driver, with normalized polar plots—first with factory tuning and then after retuning by AudioHorn:

Of course, a horn cannot correct driver anomalies, and they will be noticeable on the polar map, even if it is normalized.

Phase Plug can also be at the origin of directivity or/and temporal accident, both often linked.

Room Impact

Except in large anechoic chambers with treated ground and walls, most measurement environments, even with significant quantities of melamine, will have reflective surfaces that introduce irregularities. This can be seen in the impulse response below:

This is why most measurements are gated. It’s also important to note that our brain dynamically gates measurements, which is what we refer to as ITDG (Impulse Time Delay Gap) or integration time. ITDG is considered to be approximately one cycle (Time = 1/Hz), meaning it varies with frequency.

Woofer physical presence

Whether playing or not, the physical presence of the woofer beneath the horn will impact the horizontal polar pattern. However, the larger the speaker, the less noticeable this impact becomes as the components are further apart.

Mode detail in our diffraction and standing waves article.

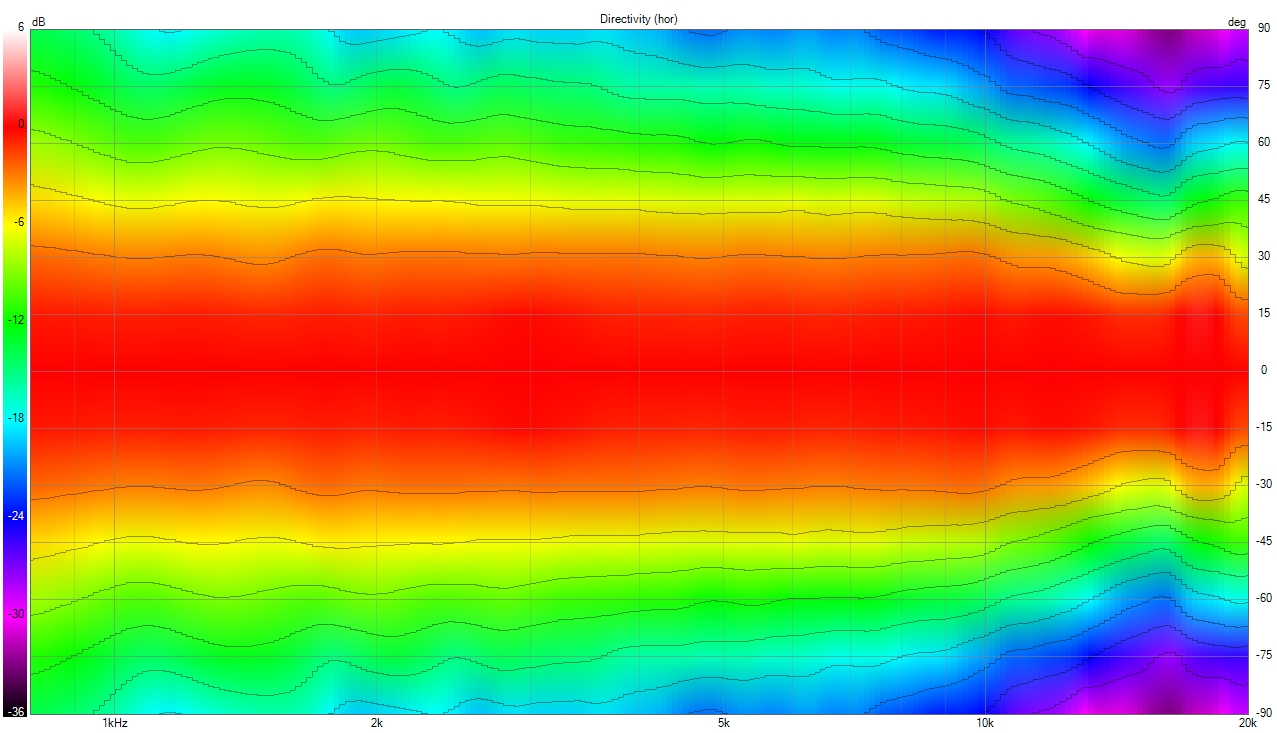

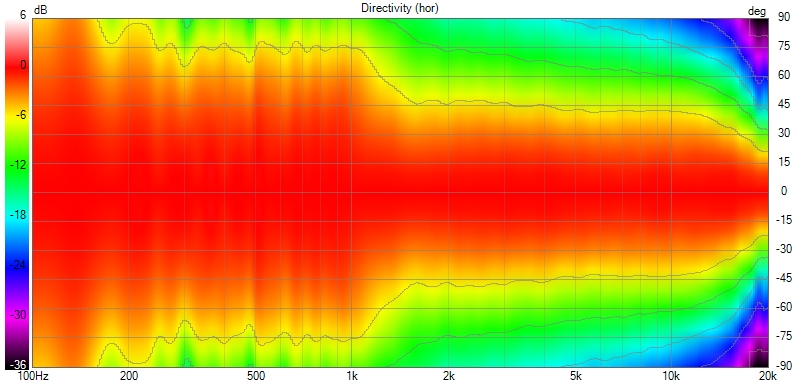

Measurement of first version X25 by clients

Below is an example of several measurements of the X25 old version, the new one is a little bit more straight after 4/5khz :

Client 1:

Conditions:

- Inside horn at 2 meters from floor and ceiling

- crossed with a mid-woofer at 1300hz

- Measuring distance: 2 meters

- Round over used: Yes

- Degree definition: 10°

- Smoothing: 1/12

- Gated: Yes

- Driver: BMS 4550

- APEX respect as turning centering point: Yes

- physical presence of woofer: Yes, realistic but alter the horn horizontal polar

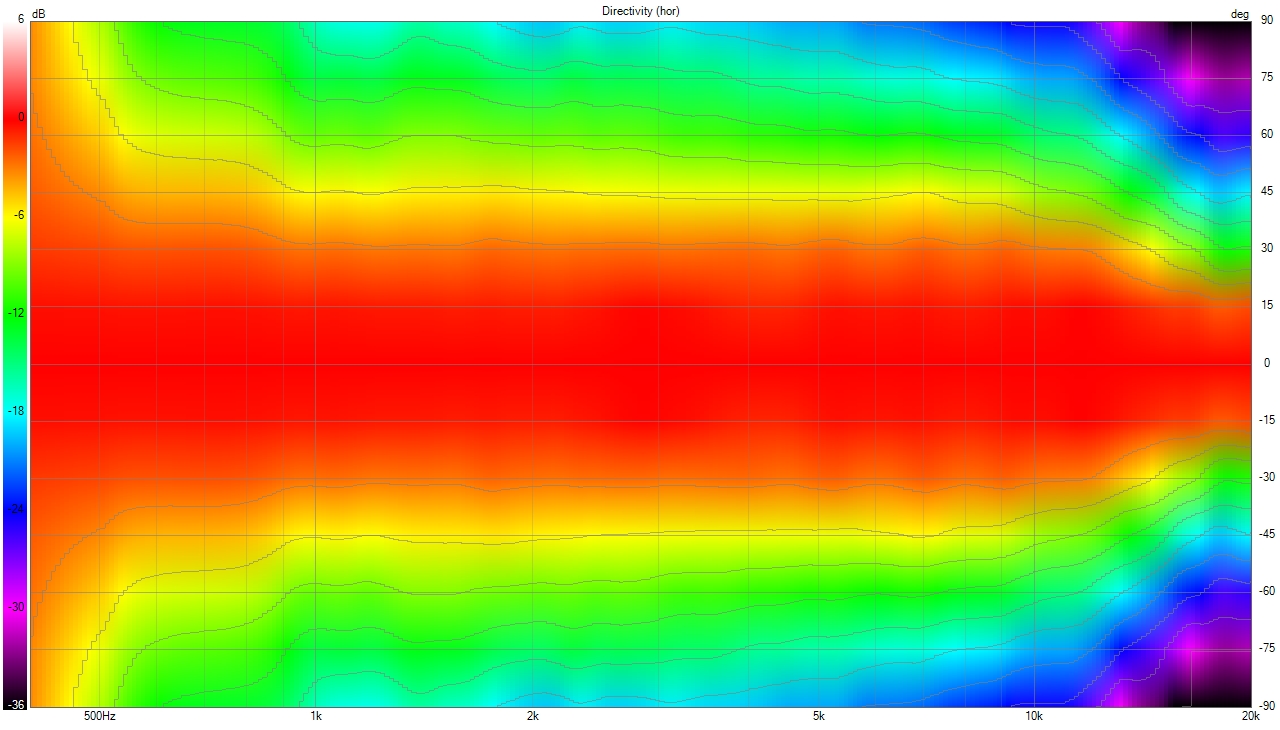

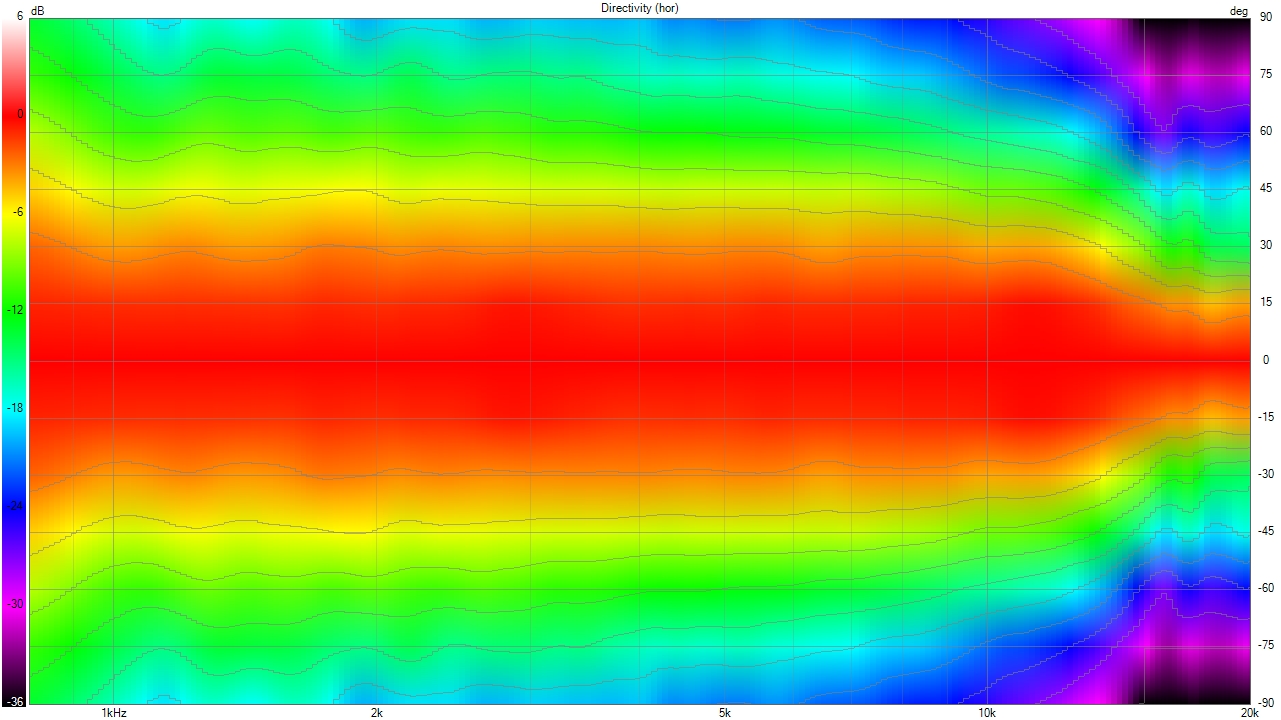

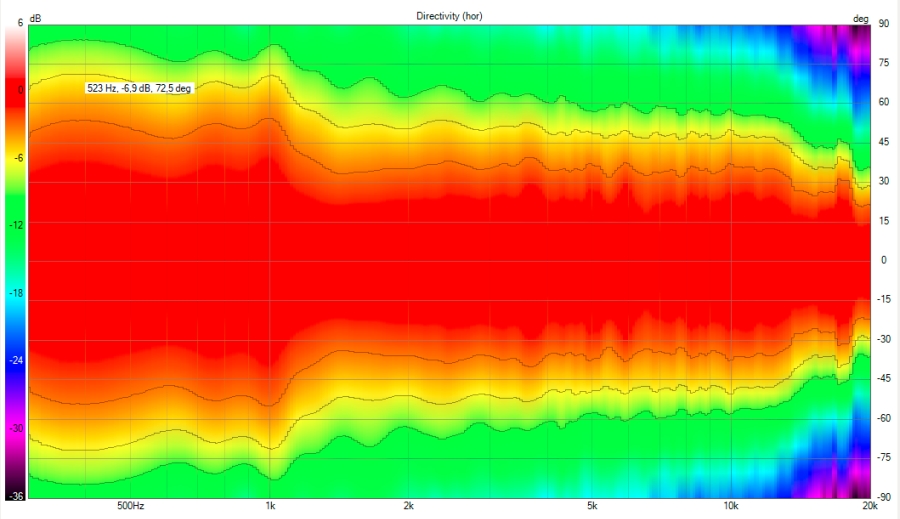

Client 2:

Conditions:

- Inside horn at 2 meters from floor and ceiling

- crossed with a mid-woofer at 1300hz

- Measuring distance: 1 meter

- Round over used: Yes

- Degree definition: 15°

- Smoothing: none

- Gated: Yes 7ms

- Driver: BMS 5530

- APEX respect as turning centering point: No, so directivity distotion is on the graph as see upper

- physical presence of woofer: Yes, realistic but alter the horn horizontal polar

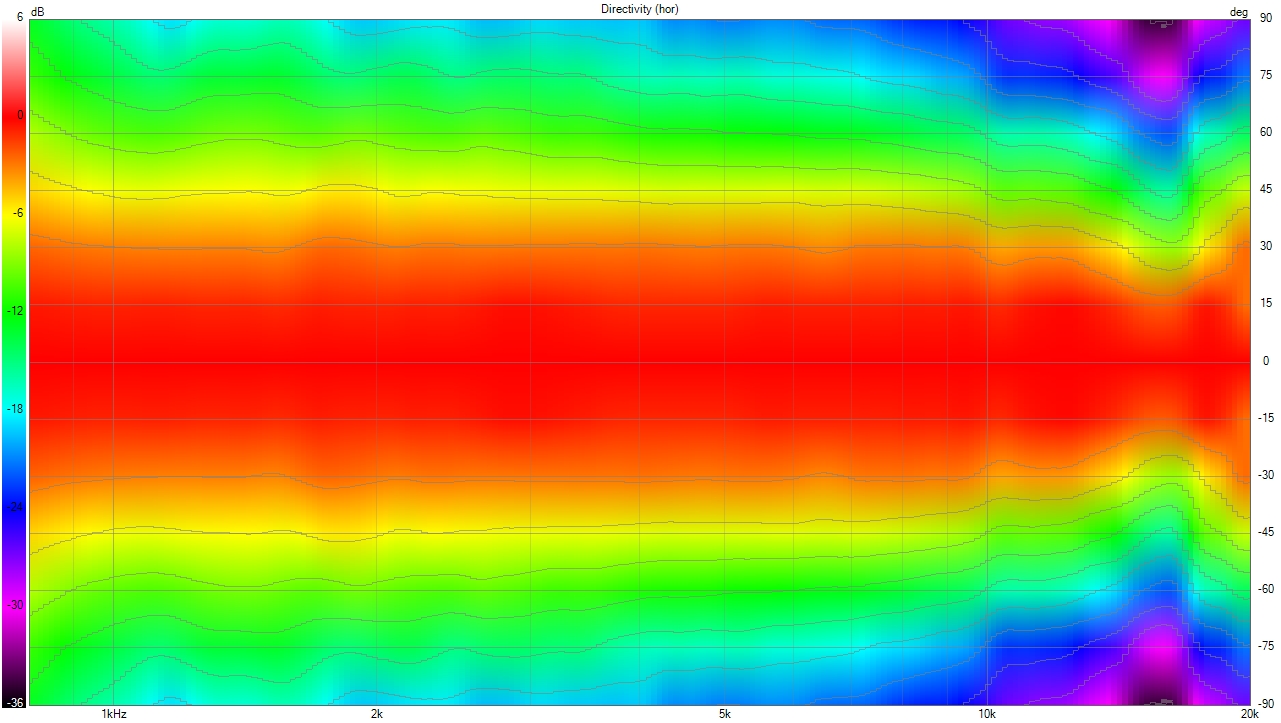

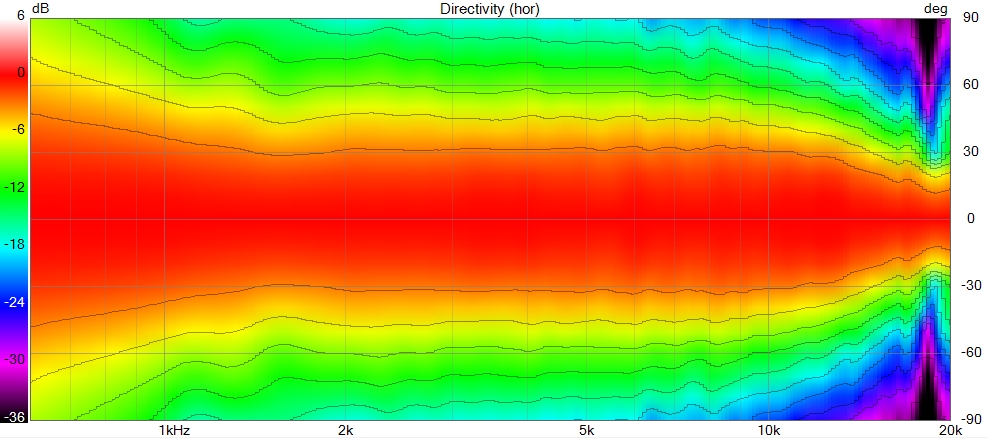

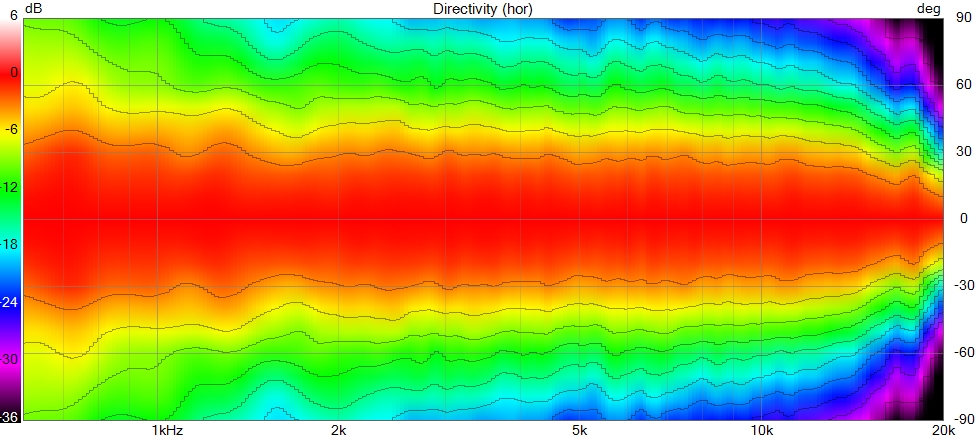

Client 3:

Conditions:

- Inside horn at 1 meters from floor

- crossed with a mid-woofer at 1250hz

- Measuring distance: 1 meters

- Round over used: Yes (final speaker)

- Degree definition: 15°

- Smoothing: 1/24

- Gated: Yes 5ms (ground reflection)

- Driver: BMS 5530

- APEX respect as turning centering point: Yes

- physical presence of woofer: Yes, realistic but alter the horn horizontal polar

Conclusion

In conclusion, the measurement methodology is crucial for obtaining accurate and reliable data. However, it is essential to avoid measuring the environment or the measurement setup itself instead of the actual object of analysis—the horn or waveguide. Interpreting the results is key, as we must keep in mind that certain phenomena, such as artifacts from compression drivers, are inevitable and cannot be corrected by the horn.

The compression driver has a direct impact on the results—phase and frequency response anomalies, breakup modes, temporal behavior, and phase plug effects—all of which leave a clear imprint on the polar plots. These effects cannot be eliminated through simple normalization or adjustments to the horn. Therefore, it is essential to account for these imperfections when interpreting the data, rather than attributing them solely to measurement errors or to the horn itself.

A solid methodology ensures that the measurements reflect the system’s actual behavior, not artifacts introduced by the environment or the measurement technique. By following rigorous practices and staying mindful of the specific characteristics of each component, we can obtain useful data for ongoing optimization and better control of directivity—while maintaining a realistic view of the system’s performance.

Sources

- Mark S Ureda - Apparent Apex Theory, 61st convention of the audio engineering society - November 1978

- Mark S Ureda - Apparent Apex, 102st convention of the audio engineering society - March 1997

- High-Quality Horn Loudspeaker System - Kolbrek - Dunker - end of 2019

- Altec - Mark S.Ureda & Ted Uzzle Technical Letter N°262

- Quadratic Throat Waveguide by Charles E Hughes

A message from Kolbrek about HornResp about directivity:

I believe Hornresp uses a Far-field approximation model for directivity, i.e. that the directivity pattern is calculated as it would appear if you measured it at a very large distance, but the level is scaled back to a 1m distance. Otherwise, you would have to specify a measurement distance and point of rotation, and there would be a large variation in the pattern depending on those values.

If the measurement point is very far away, these variations become insignificant, and the actual rotation point does not matter.

What is “very far away” depends on the size of the source (horn mouth) and also on the “apparent apex” or center of curvature of the far field wave front.

In addition, there are near-field effects. These typically happen when the distance is shorter than (Source area)/(wavelength), this distance is called the Rayleigh distance. At larger distances, the pressure varies as 1/distance, but closer to the source the variations do not follow this law, and have peaks and dips you wouldn’t see at a greater distance.

These effects are usually not a problem when measuring small devices like direct radiators and small horns, but most horns are large enough that they become noticeable, especially at the standard distance of 1m.

When measuring horns, it is usually recommended to rotate them around the “apparent apex”. This will avoid distortion of the directivity pattern at short distances compared to the far-field pattern.

Also note that Hornresp uses one-dimensional horn models, so the directivity models are only approximations.